A full lab in your hand –

for IOR/EOR, CCS/CCU and hydrogen storage

At fluidXlab, we offer a comprehensive all-in-one fluid testing technology that brings the full laboratory experience right to your fingertips. Our microfluidic systems enable the miniaturisation of various devices and lab applications, such as PVT and porous media flow solutions.

Our range of specialised micromodels – including flow assurance, porous media flow, wax and asphaltene precipitation chips, MMP chips, and foam stability chips – are complemented by unique workflows that support or even replace traditional testing processes. With fewer chemicals required and less time required compared to conventional methods, we not only provide a differentiated solution but also ensure minimal environmental impact.

WHY CHOOSE fluidXlab?

The fast and economical visualisation of fluid dynamic flow and processes helps reduce costs and accelerates investigations. This makes microfluidics an ideal solution for energy companies, IOR/EOR & PVT departments, people working in energy storage and fluid analytics (researchers, engineers), as well as researchers in the field of low carbon/environmental gases applications.

Good to know: Accurate and efficient fluid analysis performed at extreme conditions and under tight deadlines can also accelerate the implementation of net-zero projects. This ultimately results in faster decarbonisation. Additionally, employing microfluidic testing methods minimises the laboratory's environmental impact, as fewer chemicals are used in the experiments.

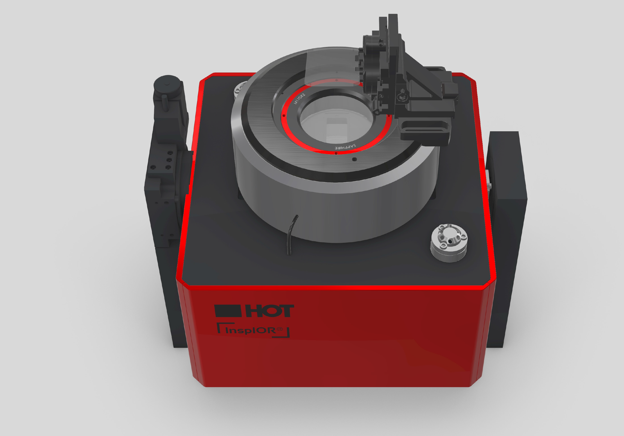

Key benefits of InspIOR®

In the past decade, we have innovated and commercialised InspIOR®, an all-in-one microfluidic fluid testing technology platform that brings the fluidics laboratory to your fingertips. It operates at extreme conditions and is fully automated, enabling safe and efficient use with minimal human interaction.

Fast and accurate fluid testing

Fast and accurate fluid testing

Precise process visualisation

Precise process visualisation

All-in-one technology platform

All-in-one technology platform

Applications

With InspIOR®, you can gain profound insights into fluid dynamics and enhanced oil recovery (EOR) techniques – thus paving the way for recovery strategies that are efficient, effective, and environmentally conscious. Explore examples of the wide range of applications of our InspIOR® microfluidic systems micromodels:

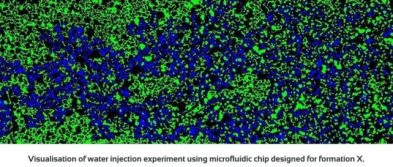

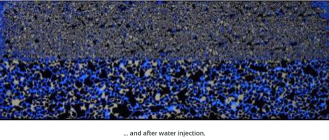

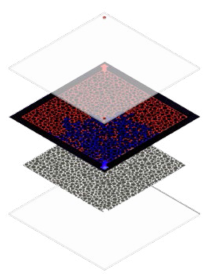

Waterflooding

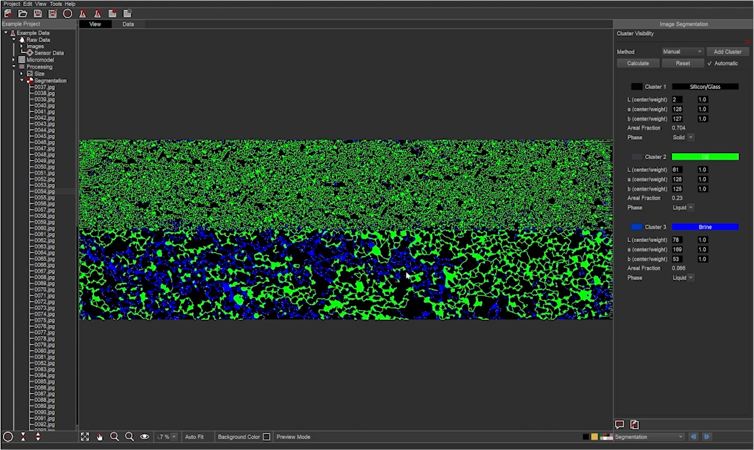

Our microfluidic systems allow for the visualisation of water injection through porous media, providing valuable insights into displacement processes. The oil phase (depicted in green) is displaced by brine (shown in blue), which is injected into the chip from the left side. This enables a better understanding of the complex mechanisms involved in fluid displacement within porous media.

MOBILITY CONTROL (POLYMERS)

With our micromodels, we can assess mobility control in enhanced oil recovery (EOR) and improved oil recovery (IOR) processes, such as polymer flooding. By utilising high-resolution visualisations, we can analyse and evaluate the effectiveness of mobility control techniques. This allows for a detailed examination of the fluid flow dynamics and the impact of polymer injection on enhancing oil recovery.

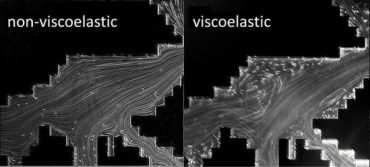

STREAMLINES & PARTICLE TRACING

InspIOR® also enables the investigation of viscoelastic turbulence effects. By studying critical parameters such as brine salinity, polymer concentration, pressure and temperature, we can explore the impact of these factors on fluid flow dynamics. This facilitates a thorough examination of how the viscoelastic properties impact turbulence and, consequently, the effectiveness of oil recovery methods.

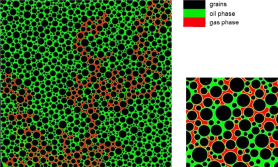

Gas injection

By studying the effects of immiscible gas injection on oil recovery, we gain valuable insights into the intricate dynamics at play. Immiscible gas injection often induces strong viscous fingering effects, leading to low oil recovery. Our microfluidic systems allow for detailed investigations, enabling a deeper understanding of the complex interactions between the injected gas and the oil reservoir.

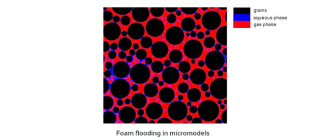

Foam

Foam is commonly used to improve the effectiveness of gas floods in enhanced oil recovery (EOR). Through the use of micromodels, we can investigate various foam-related EOR processes, including the analysis of bubble sizes, bubble count, lamella distribution, foam quality (liquid saturation), and stability. These studies are conducted under reservoir conditions, providing valuable insights into foam behaviour.

Low interfacial tension (surfactants, alkalines)

Through surfactant injection, our microfluidic systems simplify the formation of emulsions and enhance the efficiency of oil displacement. By triggering miscibility between the oil and aqueous phases, we promote the blending of these components, leading to improved fluid flow.

Good to know: Testing a multitude of chemicals is essential to determine the optimal chemical formula for a particular reservoir. In conjunction with phase behaviour tests and core floods, microfluidics serve as a valuable supplementary screening tool, effectively reducing both time and the associated costs.

Scope of services

- Phase diagram (dew point, bubble point)

- Fluid properties (density, viscosity)

- Fluid interactions (MMP, diffusion)

- EOR effect (swelling, micro/macro-emulsions)

- High Pressure, High Temperature (HPHT)

- H2 & CO2 compatible

- Asphaltene

- Wax

- Salts precipitations

- High Pressure, High Temperature (HPHT)

- H2 & CO2 compatible

- Flow through porous media (saturation profiles, recovery factor)

- Chemical IOR (polymer, alkaline, surfactant)

- Foam injection

- Gas injection

- Thermal EOR

- Microbial

- H2 & CO2 compatible

- High-pressure fluid testing micromodels (MMP, flow assurance, dew point)

- Porous media chips based on µCT and thin sections

- High Pressure / High Temperature (HPHT)

- H2 & CO2 compatible

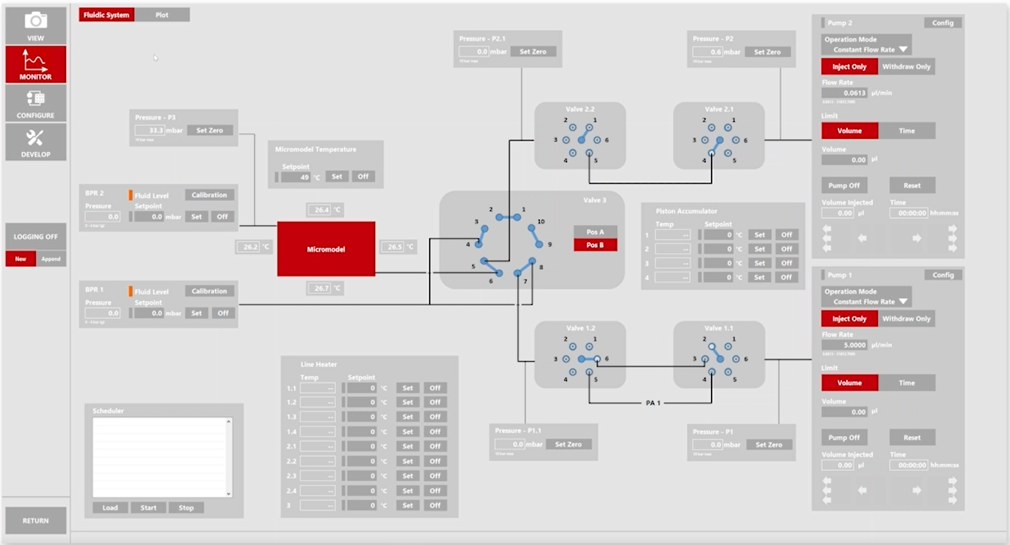

InspIOR® VISION: PROCESS CONTROL & DATA MANAGEMENT SOFTWARE

InspIOR® Vision is our state-of-the-art software solution for process control, visualisation, and data management. Designed to streamline workflows and deliver precise results, it minimises the need for human interaction. The license for InspIOR® Vision is included in the InspIOR® microfluidics system (one license per package).

InspIOR® VISION PRO

The extension module InspIOR® Vision Pro for enhanced image processing capabilities and visualisation grants you access to additional powerful features for analysing displacement and flooding results – for instance, generating recovery curves and assessing phase saturation distributions.

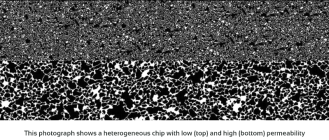

“Rock-on-a-chip” and fluid testing micromodels

Together with our microfluidic system, we also offer customised and off-the-shelf micromodels. Our transparent glass-silicon-glass (GSG) micromodels provide full visual access, enabling the study of small pore throats, complex flow geometries and reservoir conditions. Additionally, you benefit from precise wettability control for accurate experiments.

Publications

Our most recent work was featured in the following publications:

Selecting EOR Polymers through Combined Approaches—A Case for Flooding in a Heterogenous Reservoir

Borovina, Ante, Rafael E. Hincapie, Torsten Clemens, Eugen Hoffmann, and Jonas Wegner. 2022.

Polymers. 2022; 14(24):5514.

https://doi.org/10.3390/polym14245514

Real structure micromodels based on reservoir rocks for enhanced oil recovery (EOR) applications

Calvin Lumban Gaol, Jonas Wegner and Leonhard Ganzer

Lab on a Chip, 2020, 20. Jg., Nr. 12, S. 2197-2208.

https://doi.org/10.1039/D0LC00257G

Coupling Microfluidics Data with Core Flooding Experiments to Understand Sulfonated/Polymer Water Injection

Tahir, Muhammad, Rafael E. Hincapie, Nils Langanke, Leonhard Ganzer, and Philip Jaeger. 2020.

Polymers 12, no. 6: 1227.

https://doi.org/10.3390/polym12061227

The Next Generation Lab

InspIOR® - Microfluidic Technology Platform

Brochure

Download

Fluid testing redefined

InspIOR® - Microfluidic Technology Platform

Flyer

Download

Fluidic Systems - Turnkey Microfluidic Solutions

Flyer

Download

Advanced Carbon Management Solutions

BROCHURE

DOWNLOAD

Advanced Hydrogen

Laboratory Solutions

FLYER

DOWNLOAD

CCS/CCU Fluid Characterisation

FLYER

DOWNLOAD

Next-Generation Microfluidic Pumps

FLYER

DOWNLOAD

Get started now!

Experience the power of InspIOR® and revolutionise your fluid testing processes for CCS/CCU, hydrogen and underground storage. Get in touch with us today to enjoy a full lab experience right at your fingertips, in the palm of your hand!

Discover what others say about fluidXlab

We invited HOT fluidXlab to provide laboratory support in our research of potential candidates for underground hydrogen storage (UHS) in Austria. HOT fluidXlab never ceased to impress with their professionalism, persistence and surpassing any our expectations in delivering highly valuable and reliable data.

Dr. Clemens T., Senior Reservoir Engineering Advisor at OMV Energy