Phase behaviour and PVT measurements for laboratories

fluidXlab’s PVT (pressure-volume-temperature) analysis equipment is the ideal solution for oil and gas measurements at PVT laboratories, addressing the complex challenges of the energy transition.

We know how important it is to obtain reliable data quickly and efficiently. That’s why we have developed a system that helps you streamline your lab processes. The fully automated and integrated turnkey solution offers precise characterisation of complex liquid mixtures under extreme conditions – with minimal human intervention required.

Good to know: We also offer microfluidics testing as an add-on option to make measurements even faster and more accurate. With this option, you can gain a better understanding of your fluid mixtures and receive precise results in virtually no time at all.

WHY CHOOSE fluidXlab?

We understand that every laboratory has its own unique needs, which is why we also offer a bespoke systems service. Our team of experts is happy to work with you on customising your PVT analysis equipment to meet your exact requirements. By offering a very high level of service, we can ensure you will have the best possible experience working with us.

Benefits of our PVT analysis system

Fully automated

PVT analysis

Fully automated

PVT analysis

Full spectrum

of experiments

Full spectrum

of experiments

Key features of the fluidXlab PVT analysis system

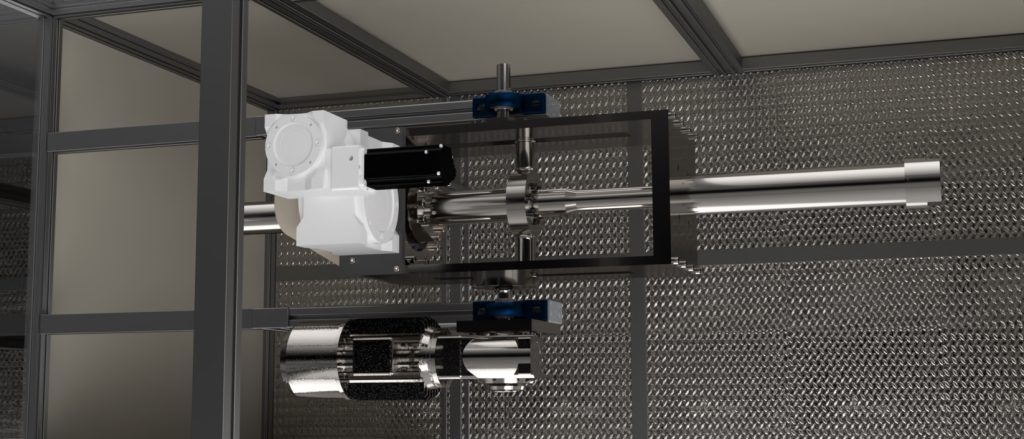

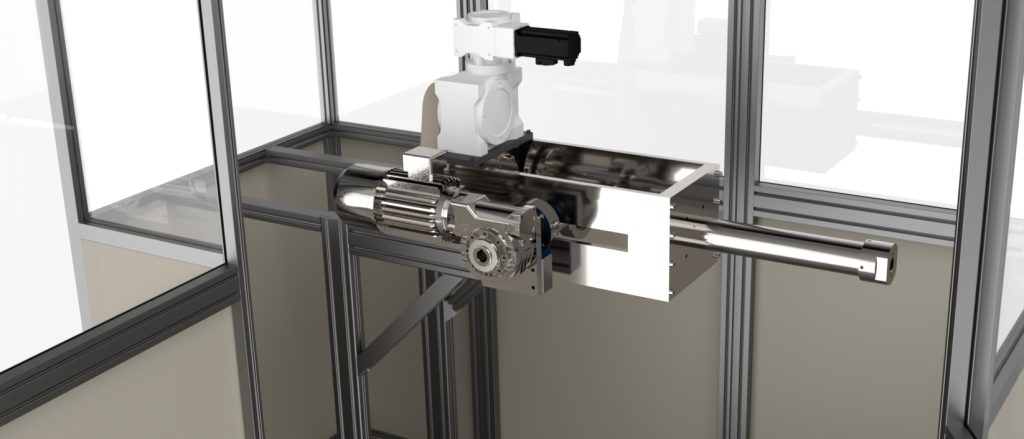

The visual PVT analysis system is a comprehensive system designed to provide precise and accurate measurements. It includes a 500-ml view cell with an integrated direct-driven high-precision piston and an integrated stirrer for proper mixing and fast equilibration. The full fluid volume can be easily monitored with the integrated camera.

Additionally, users can upgrade the system with optional features such as a density meter, gas chromatography, gas meter, or gas viscometer to further expand its capabilities.

The most important features at a glance

- Integrated stirrer

- Ultra-low dead volume

- Maximum operating pressure 700 bar

- Laser detectors for accurate dew point measurement

- Microfluidics hook-up

- Densitometer, Viscometer

- Gas Chromatography

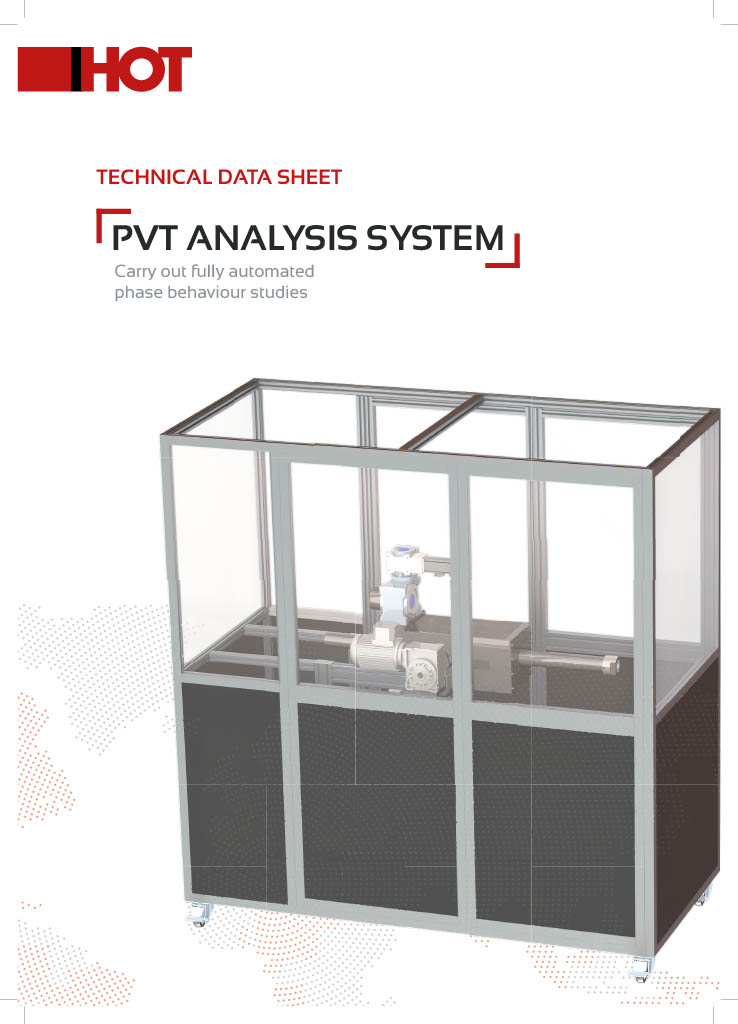

TECHNICAL DATA SHEET

For more in-depth information on the various features of our PVT analysis system, please have a look at the technical data sheet provided below:

TECHNICAL DATA SHEET

The PVT Laboratory

PVT and phase behaviour testing for oil & gas, CCS/CCU and hydrogen:

Brochure Download

Advanced Carbon Management Solutions

Brochure Download

CCS/CCU Fluid Characterisation

Thermodynamic and transport properties of CCS/CCU fluids:

Brochure Download

Streamline your PVT analysis processes!

With our fully automated system, microfluidics integration and bespoke solutions, you can trust us to provide you with one of the most advanced and efficient PVT analysis systems on the market. Get in touch with us today to learn more about how our equipment can benefit your lab and how we can work together to meet your unique requirements.